Space Optimization in Warehouse

Effective space optimization is the cornerstone of maximizing a warehouse’s storage capacity. With an increasing number of items to store, ever-increasing consumer demand, and limited land resources, warehouses must adopt innovative strategies to utilize all available space smartly without compromising accessibility or operational flow. Here, we explore the importance of space utilization, the challenges of achieving this, and the solutions provided by 3PLNext.

Importance of Optimum Space Utilization

Space optimization is crucial in warehousing because it improves order processing and fulfillment speed, lowers operational and additional costs, and ensures better control over supply management.

- Cost Reduction: Effective space utilization prevents the need to install additional storage, lowering construction, rental, and maintenance costs.

- Improved Supply Management: Optimum space utilization helps maintain an easily accessible and well-organized inventory, enhancing speed and efficiency in managing supply.

- Scalability: Efficient use of space helps scale operations easily and accommodate growth without immediately expanding physical storage space.

- Enhanced Productivity: Optimum storage use enables a smoother working flow and reduces travel time for picking and packing operations, increasing productivity.

- Safety and Compliance: Optimized space ensures adherence to safety regulations, reducing the risk of hazards and resulting in a much safer working environment.

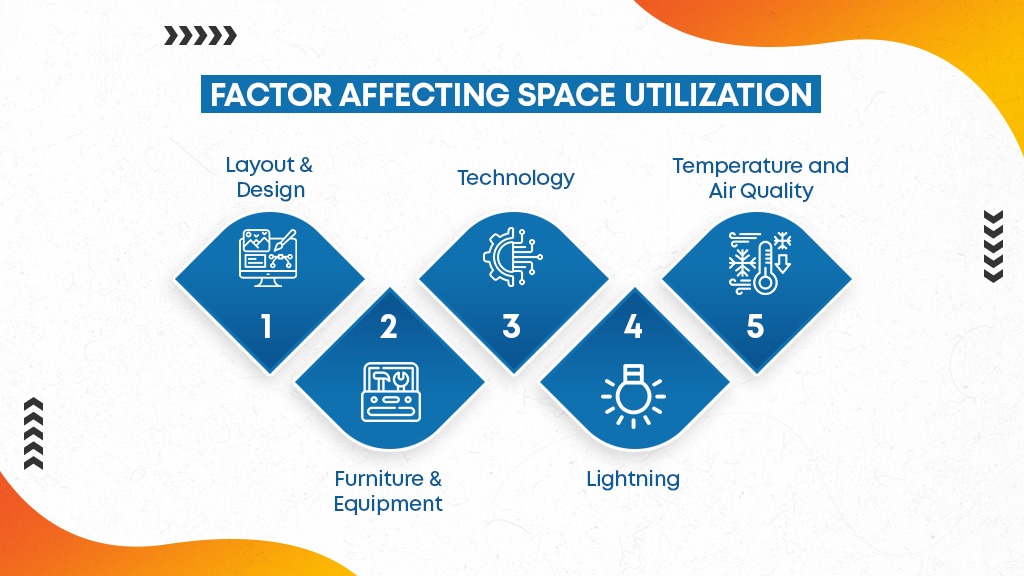

Challenges of Space Utilization

Although warehouse storage is an important part of warehousing, several limitations, such as inadequately used storage and inappropriately designed infrastructure, prevent it from being optimized effectively.

Poor Architectural Design: Most warehouses are designed in such a way that it becomes difficult to achieve optimum space utilization or operational efficiency. Poorly designed infrastructure makes accessing stored goods a difficult and tedious task.

Fluctuating Supply Levels: Warehouses need to manage changing supply levels at seasonal holidays and other times due to varying demand. Efficient space management is necessary to maintain the smooth running of operations.

Product Diversity: Managing a diverse range of products, including different shapes, sizes, and types, complicates supply management and space optimization. Many goods also require specialized storage areas, which complicates matters

Implementing Safety Regulations: Adhering to safety regulations while utilizing space optimally is difficult since there are strict guidelines on storage heights, aisle widths, etc., to protect workers.

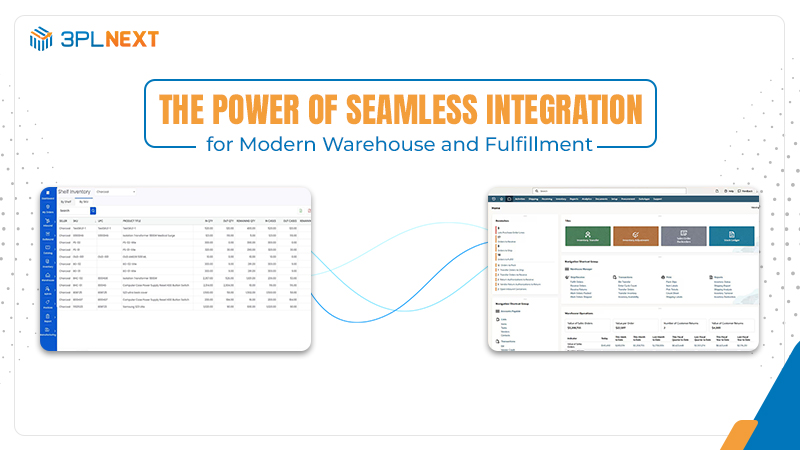

3PLNext’s Solutions for Optimum Space Utilization

3PLNext offers advanced warehouse management solution to utilize space effectively while maximizing warehouse efficiency.

Intelligent Warehouse Architectural Design: Warehouse infrastructure should be properly designed so that no space is wasted and the maximum amount of goods can be stored in the least amount of space.

Vertical Storage: Utilizing vertical space via ceiling storage units or high shelves prevents overcrowded floors. 3PLNext’s software can manage these systems to ensure optimal use of vertical space.

Automation and Robotics: 3PLNext uses technologies such as AGVs, drones, conveyors, etc. to streamline operations and maximize all available space by enabling efficient movement of goods.

Cross-docking: 3PLNext implements cross-docking strategies to minimize the need for long-term storage of certain items. Some goods are directly transported to outbound shipping areas, reducing storage space requirements.

Space optimization is essential in warehousing to support scalable operations. 3PLNext offers innovative strategies and solutions to tackle space optimization challenges, such as vertical storage solutions and proper warehouse design. With 3PLNext, businesses can achieve outstanding operational performance.

Leave a Reply